Who We Work With

Trusted by over 10,000 OEM/ODM partners worldwide.

26Years+

Manufacturing Expertise

50000M²+

Modern Factory

100000+

Daily Output

30Min+

Design Output

WHAT WE OFFER

Custom Plastic & Stainless Steel Bottles Manufacturer

We offer a wide range of drinkware, including plastic water bottles, plastic tumblers, travel mugs, stainless steel vacuum flasks, stainless steel water bottles, and aluminium bottles. All our products are certified by FDA, RCS, GRS, GLF, and ISCC for safety, sustainability, and quality.

One-Stop OEM/ODM Bottle Solutions

We specialize in full-range customization of water bottles and cups for your brand, promotion, or wholesale needs.

Texture Mapping

Users can upload their own images or choose from a vast library of designs, allowing for online editing and application of patterns directly onto the product. The system generates a highly accurate 3D preview of the final product with the applied texture.

Engraving Simulation

The engraving feature provides a realistic simulation of laser engraving effects, allowing users to visualize precise etching and customization on the surface of the cup or bottle.

Part Replacement

Customers can easily swap out components like lids or other attachments in real-time, providing flexible customization options for different product models.

Color Customization

Every part of the product can be color-customized, with the option to match Pantone color codes. This ensures brand consistency and gives users full control over the visual appearance of the product.

High-Quality Image Output

Users can generate high-resolution images of their customized products, including the ability to place them in virtual scenes for studio-like shots. The system allows for quick output of professional-grade visuals, perfect for marketing and promotional use.

Idea

Customers tell us their ideas or

show us any photo about what they

want to make.

show us any photo about what they

want to make.

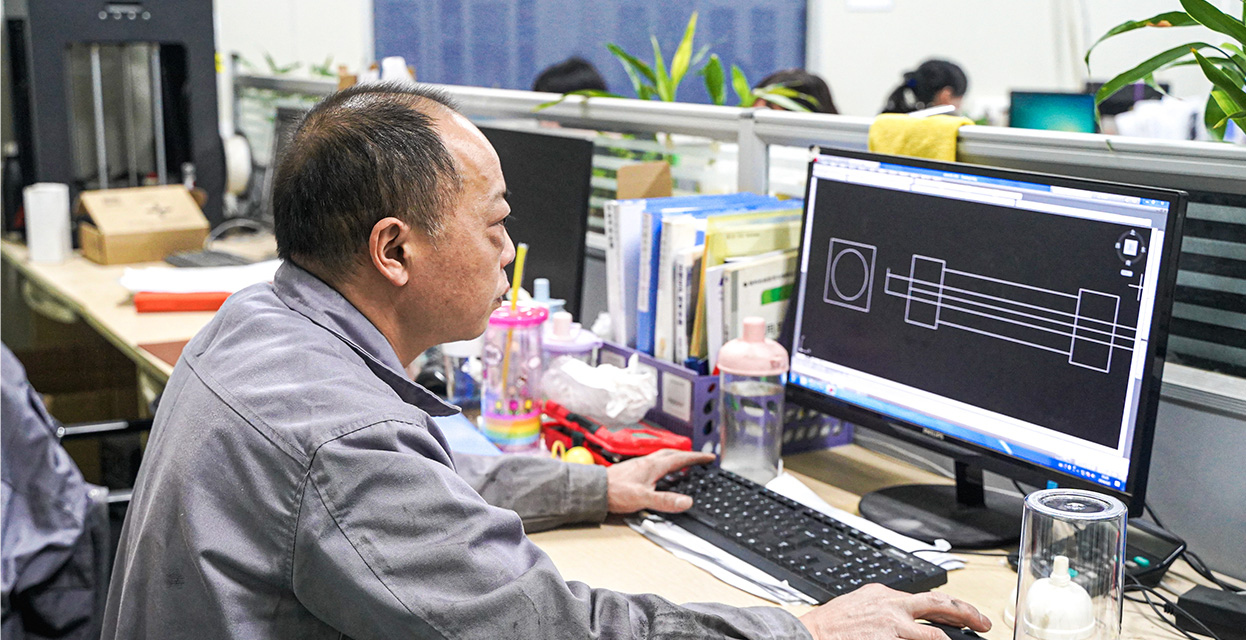

2D Drawing

We will make 2D drawing according

to customer's requirement.

to customer's requirement.

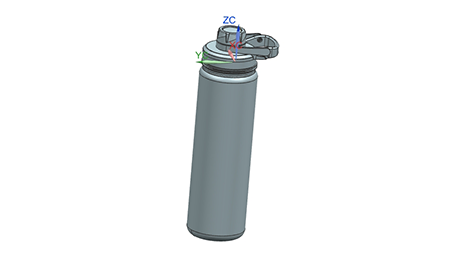

3D

Then we will make 3D drawing.

Prototype

Confirm the structure and the function.

Mould

Open mould as customer's request.

Sample

We will send test sample to brand

customers.

customers.

Plastic Bottles Production Process

Raw Material Inspection

lnjection Molding

Blow molding

Printing

Shipping

Finished Goods Warehousing

Packaging

Inspection

Why choose us for plastic and stainless steel bottles?

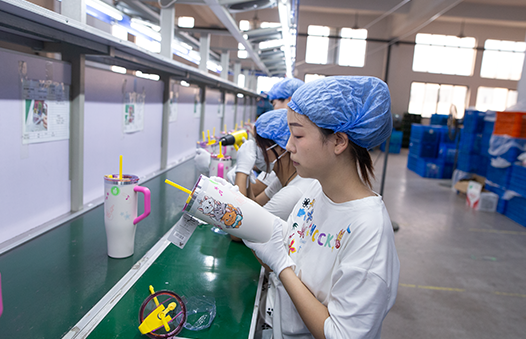

Plastic Bottles Factory

9,000m² Dust-Free Production Area

110 Fully Automatic Injection & Blow Molding Machines

50,000+ Daily Production Capacity

2 Packing Lines with 40 Workers Each

2,000m² Packing Workshop

500m² Printing Workshop

Stainless Steel Bottles Production Process

01.Pipe Cutting

02.Pipe Rolling

03.Hydroforming

04.Cup Separation

05.Head Cutting

06.Shaping

07.Cup Washing

08.Cup Sorting

09.Vacuuming

10.Bottom Welding

11.Rim Grinding

12.Polishing

13.Temperature Testing

14.Printing

15.Inspection

16.Packaging

Stainless Steel Factory

20,000m²

Factory Area

130+

Professional Machines

120+

Skilled Operators

40 Design engineers

offering free design service

Quality Control

1

Raw Material Check

2

Dual Temperature Testing

3

Semi-Finished Check

4

Electrolysis Check

5

Polishing Check

6

Pre- Packaging Check

7

Mid-Line Check

8

Final Inspection

9

AQL Sampling

Qualification Certification

Partial Product Patent Certificate

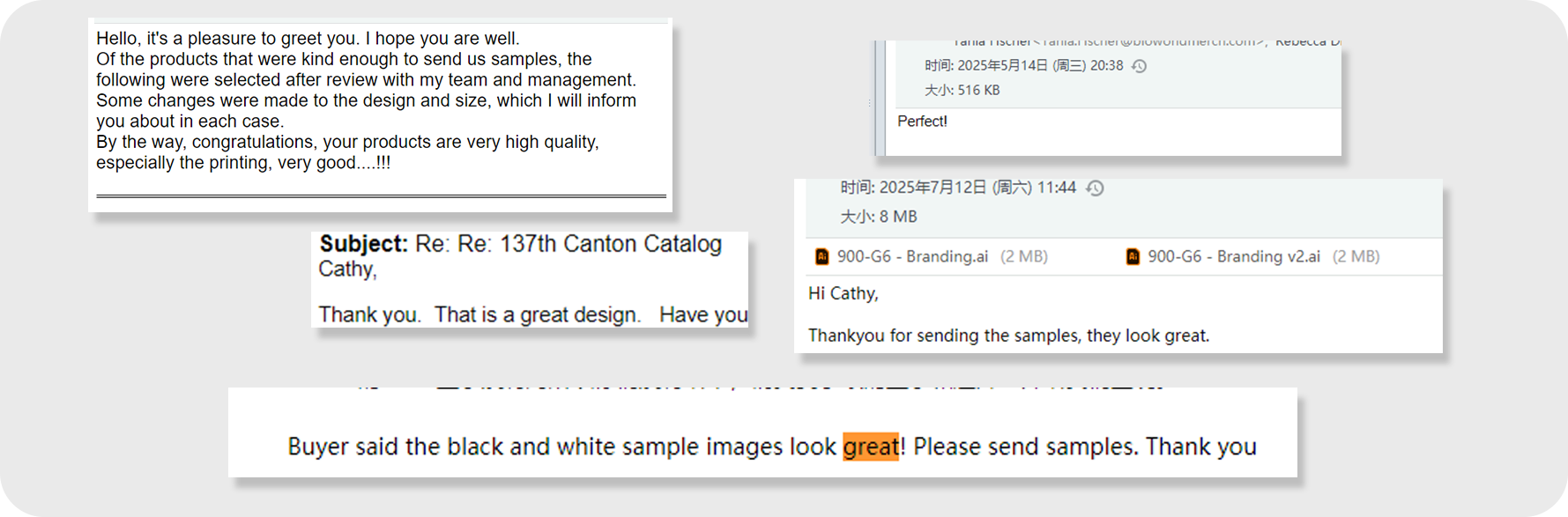

Join Our Bottle-Delighted Customers

Need a reliable manufacturer for your custom design water bottle?

Eco-Friendly Water Bottles for Your Business

We use recyclable materials, eco-friendly processes, and hold certifications like FSC, BSCI, and ISO14001. Sustainability is our ongoing commitment.

FAQS

Q1: What certifications do you have?

ISO 9001, ISO 14001, FDA Compliance, BSCI, Disney FAMA...

Q2: What is the MOQ for wholesale orders?

Our minimum order quantity (MOQ) ranges from 1,000 to 3,000 pieces, depending on the product type and customization requirements.

Q3: Can I get samples, and how long is the sample lead time?

Yes, samples are available. The sample lead time is approximately 15–20 days. For detailed sample policies, please contact our sales team.

Q4: What are your payment terms and shipping methods?

We accept T/T as the payment method.

Shipping is typically arranged FOB, or you can choose your preferred shipping method, either by sea or by air.

Shipping is typically arranged FOB, or you can choose your preferred shipping method, either by sea or by air.

Q5: How long is your production lead time?

Our standard production lead time is around 30 days, depending on the order quantity and customization requirements.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic